WHAT IS AN ELECTRIC LIFT TABLE?

Electric lift tables are a practical solution for industrial moving, positioning, and load transferring. They not only improve productivity but enhance workplace safety, as well, by eliminating the need for workers to perform repetitive bending and lifting. Lift tables are also a cost-effective method of obtaining a larger work area.

In comparison to manual or foot pedal hydraulic lifts where pistons and compression result in unstable movements, electric lifts are much smoother and more precise. A hydraulic power unit and cylinder offer a self-contained oil reservoir to minimize oil leaks. The motors for electric tables can either be direct (DC) or alternating current (AC). Identifying the most suitable motor depends on the table’s purpose; however, the most commonly used option is 110 VAC. For maximum ease of use, many electric lift tables have a hand pendant to activate lifting and lowering.

HOW ELECTRIC LIFT TABLES IMPROVE PRODUCTIVITY AND SAFETY

Electric lift tables from Unidex make it possible for workers to lift products safely, without risking injury or expending unnecessary energy. In high-cycle applications, electric lift tables deliver significant time savings while providing improved ergonomics. They operate smoothly and quietly, with no setup required. Electric lift tables are also quicker and more efficient than laborers. The bench top is supported by steel tubes, creating a strong and rugged work area. The standard area is 30” x 60 “ and 1-3/4” thick with hard maple wood. Fixtures and work holders can be easily screwed to the top. Casters can also be added for flexibility in moving the work area to a different location.

MAIN CONSIDERATIONS WHEN SELECTING AN ELECTRIC LIFT TABLE

To identify the most suitable table lift for your application, there are four main factors to consider:

CAPACITY

Most material handling applications require 1,000 lb capacity or less.

SIZE

Determine the ideal physical dimensions of the lift table to ensure it will fit in your facility.

STROKE

The lift table’s elevation capability, from contraction to full expansion.

CYCLE

How often this lift table be used

OPERATIONAL MANNER

The mechanism that provides lift to the table. See “Types of Lift Tables” below.

TYPES OF ELECTRIC TABLE LIFTS BY MECHANISM

Electric lift tables from Unidex are available in four lifting mechanism styles:

- Electric Hydraulic Workbench

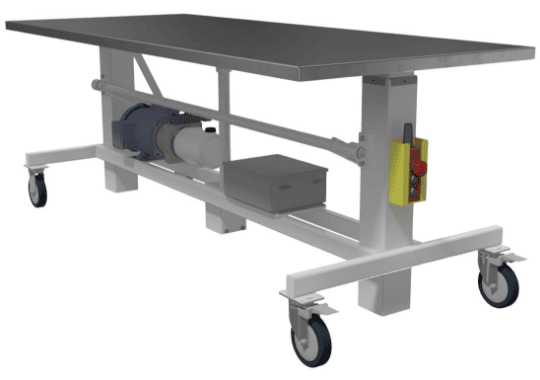

Electric Hydraulic Workbench

Uses a single cylinder and hydraulic power unit to lift two telescoping columns that support the workbench in a cantilevered position. Locking casters can be added in the event of cleaning or easily repositioning the unit.

- Portable Lift Table

Portable Lift Table

Uses a linear actuator with DC or AC motor. The DC unit will have a battery and on board charger. Typical stroke is 48″.

- ECL

ECL

Uses an AC gear motor with chain and sprocket for powered up and down travel. A platform is connected to a carriage that travels vertically on a column. This unit is used for high travel. The gear motor can also be preset with limit switches for start and stop positions.

- Pallet Lifts

Pallet Lifts

A large platform attached to a heavy wall mast for lifting or lowering heavy pallets of product. This device uses a large bore cylinder and hydraulic power unit. It is powered in the up and gravity controlled for downspeed.

CUSTOMIZATION OPTIONS FOR YOUR ELECTRIC LIFT TABLE

Electric lift tables from Unidex are fully customizable to your needs. You can select your desired fixtures, tilt capabilities, table mobility, and more.

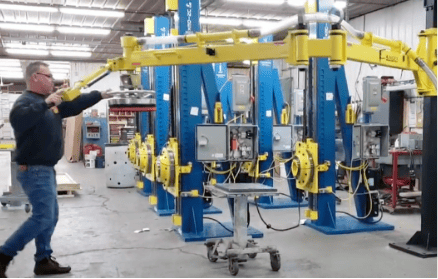

APPLICATIONS OF ELECTRIC LIFT TABLES

Any workplace that requires lifting, moving, or palletizing can benefit from quality electric lift tables. Solutions from Unidex are used throughout a wide variety of industries, including:

AUTOMATION

Freight lift and conveyor systems, automatic indexing lift, load positioning

WORK HANDLING/INDUSTRIAL Load lifting, ergonomic work positioning, palletizing, unloading palletizing, order picking.

HEAVY MACHINERY

Vehicle loading and docking operations, automotive repair tasks.

ASSEMBLY OR INSPECTION

Supporting product in an ergonomic position for each worker

Additionally, as a provider of customized material handling solutions, Unidex develops products tailored to the needs of challenging environments, such as cleanrooms, metalworking, warehousing, and more.

ELECTRIC LIFT TABLES BY UNIDEX

Unidex solves material handling challenges with ergonomic solutions for virtually any industry. Our standard product lineup is versatile enough to solve most lifting needs; however, we also gladly make modifications when needed. All of our products are made in America and ship globally.

You can learn more about our electric lift tables by visiting our product pages:

- EHW Series Easy-Lift Electric

EHW Series Easy-Lift Electric Workbenches

The Unidex EHW Easy-Lift Electric workbench is specially designed with a powerful electric/hydraulic lift system to lift heavy loads expediently.

- PH Series Worktables

PH Series Worktables

PH Series mobile hydraulic lift tables offer flexibility and versatile capability to solve the bulk of material handling problems in the workplace such as assembly operations and portable workstations.

- PE Series Light Duty Lifts

PH Series Light Duty Lifts

PE Series Light Duty Lift Workstations provide a compact and agile way to handle repetitive lifting of loads that are too heavy for manual lifting but not so heavy as to warrant the use of more expensive equipment.

- PE Series Standard Duty Lifts

PE Series Standard Duty Lifts – Scissor Lift Alternative

PE Series Heavy-Duty workstations are designed for the frequent lifting of heavy loads and to meet special positioning needs.

- PE Shaft Handling Mobile Lifts & Electric Lift Workstation

PE Shaft Handling Mobile Lifts & Electric Lift Workstation

PE Series mobile electric lift workstation for shaft handling are custom-designed units that feature a shaft head to provide ergonomic positioning and locking on the shaft end.

In addition to our range of standard electric lift tables, we also engineer custom lifting products. Our experienced team can help you develop a cost-effective solution that meets all of your process requirements. If you have any questions about our products or would like to discuss a custom lifting solution, contact our team today.

Whether mechanical, electrical, hydraulic or pneumatic Unidex products are reliable and easy to operate.

Our products are backed by a comprehensive one-year warranty and are available factory-direct or from dealers and distributors in the United States and Canada.